Metal Powder

In metal additive manufacturing (3D printer) technology, equipment development is desired to contribute to Digital Transformation (DX) of the manufacturing industry the near future. Therefore, it is indispensable for the metal additive manufacturing technology to be digital transformed, and for the characteristics of the metal powder to own no residual gas and be spherical. This is the most important material requirement for the construction of digital twins in the metal additive manufacturing process.

In addition, for the production of powder forged products such as turbine discs, the use of gas-free metal powder is an indispensable requirement for achieving a reliable level of fatigue strength of the product.

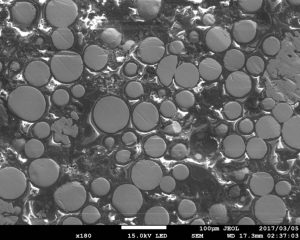

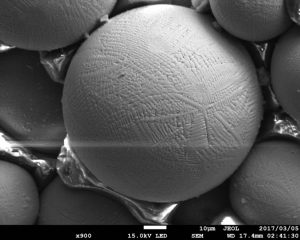

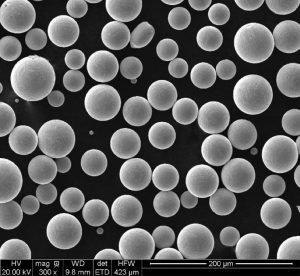

About 20 years ago, we have been conducting research and development on the production of spherical metal powder with a circularity ~1 without residual gas or satellite adhesion through the plasma rotating electrode method (PREP).

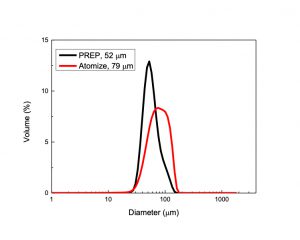

At the time of its launch, the technology was at a standstill, and it was difficult to produce fine powders of 200 μm or less. However, at present, with technology development progressing, and we have succeeded in producing fine powders of 50 μm or less.

We have learned from it and succeeded in developing a mass-produced PREP powder manufacturing equipment using next-generation PREP technology.

The PREP has a process feature that it tends to be a sphere, and there is no atomizing gas induced residual gas pore or satellites as defect. We have developed the world’s first technology to control the electrode rotation speed of ≥40,000 rpm. With our ultra-ultra-high-speed electrode rotation technology, the particle size of alloy powder with a sharp particle size distribution can be controlled in a wide range from several microns to several hundred microns by variously controlling different droplet formation process with the inherent material tension.