Equipment

High-speed plasma rotating electrode spherical powder fabrication equipment

Specifications

1.Equipment Overview

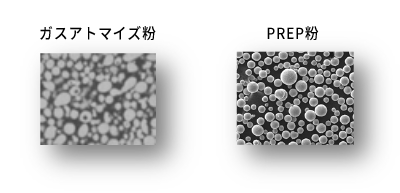

Plasma Rotating Electrode Process (PREP) is a technology that melts a high-speed rotating electrode rod by plasma irradiation and scatters molten metal by centrifugal force to produce metal powder. However, coarse powder is the only disadvantage for the PREP powder fabrication. One of the causes is insufficient centrifugal force. Under the guidance of Professor Akihiko Chiba of the Institute of Materials Research, Tohoku University, we have developed a new PREP equipment with unprecedented maximum rotation speed and maximum electrode diameter. The productivity of fine powders has increased due to the much larger centrifugal force than the conventional equipment. Furthermore, since it is possible to control the atmosphere inside the chamber, it is advantageous for research such as dissolution and solidification of scattered powder.

In addition, since our company is founded with the support of active prominent researchers at Tohoku University on the fields of materials, space, machinery, and fluids, so that we are promoting research and development while receiving unprecedented support for advanced technology and advice on research.

This equipment can handle a wide variety of options for performing manufacture in small quantity and many kinds. Thus, it is possible to supply the optimum powder for manufacture in small quantity and many kinds required for material development and advanced material research. Application includes metal 3D printing, ultra-quenching solidification alloy manufacturing, and metal powder materials for powder forging.

2.Equipment features

| Method | Quality (shape, pore, etc.) | Fine powder productivity | Contamination | Gas control in chamber |

|---|---|---|---|---|

| Gas atomize | Bad | Good | Bad | Impossible |

| Current PREP | Good | Bad | Excellent | No |

| New PREP | Excellent | Good | Excellent | Available |

3.Specifications

- Motor Rotation Speed: Max40000rpm

- Electrode Rod Diameter: φ50~100mm

- Electrode Travel Distance: >50mm

- Gas Atmosphere Control: Available

- Variety of options

4.Equipment configuration

- Vacuum chamber

- Electrode rotation mechanism

- Electrode feeding mechanism

- Plasma mechanism

- Atmosphere control unit

5.Producible powder size

- Ti6Al4V: Average powder size(70μm)20~150μm

- Inconel718: Average powder size(50μm)10~100μm